Wax Chase

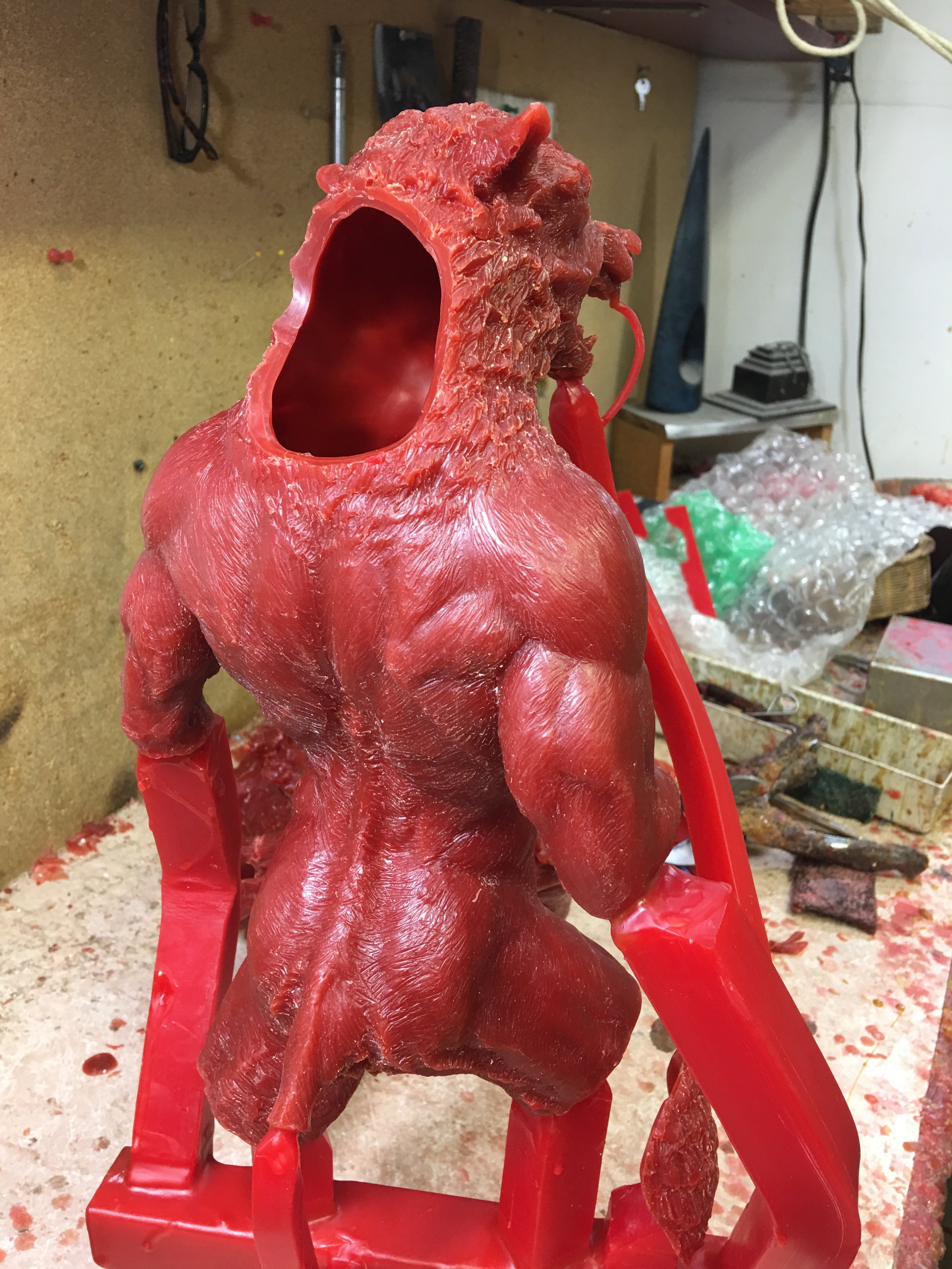

Now that we have a detailed wax copy of the original sculpture, our trained wax chasers now clean up the wax.

Using many of the same tools that the artist uses to sculpt the original, our wax chasers clean up air bubbles, seams (from connecting areas of the mold), and any imperfections so as to match the texture and essence of the artist's original sculpture.

Wax Sprue

After the wax is cleaned, a circulatory system must be created and attached to support the wax model and leave passageways or tunnels through which the melted wax escapes from the slurry shell to permit the molten metal to enter the pattern chamber of the casting flask.

This system is created by attaching sprues (wax bars) and a pouring cup to the wax pattern to insure the proper flow of metal and to control the metal solidification.

Spruing is more important to casting than is generally realized. In fact, it is essential that sprues are properly engineered to each individual sculpture in order to create a flawless casting. We have been perfecting this technique for years through study and research because an accurately sprued sculpture is imperative to creating the highest quality bronze.